Discovery of a new precipitation pathway involving the direct transformation of coherent precipitates through the assistance of vacancies

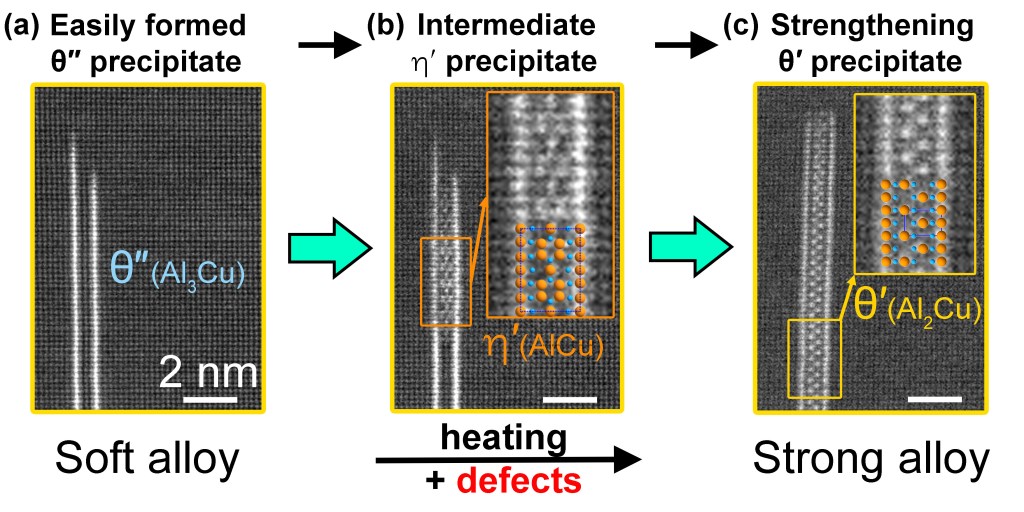

This work deals with a classic case of difficult phase transformations, namely the nucleation of the strengthening precipitate phase θ′ in the aluminium-copper alloy system. We show that this transformation can be promoted in samples exhibiting at least one nanoscale dimension, with extremely high nucleation rates for the strengthening phase as well as for an unexpected phase. This template-directed solid-state nucleation pathway is enabled by the large influx of surface vacancies that results from heating a nanoscale solid.

This work was published in Nature Communications in March 2020.

Discovery of a new class of interfaces between crystalline phases (or heterophase interfaces), in two of the best-known aluminium alloy systems: Al-Cu and Al-Ag.

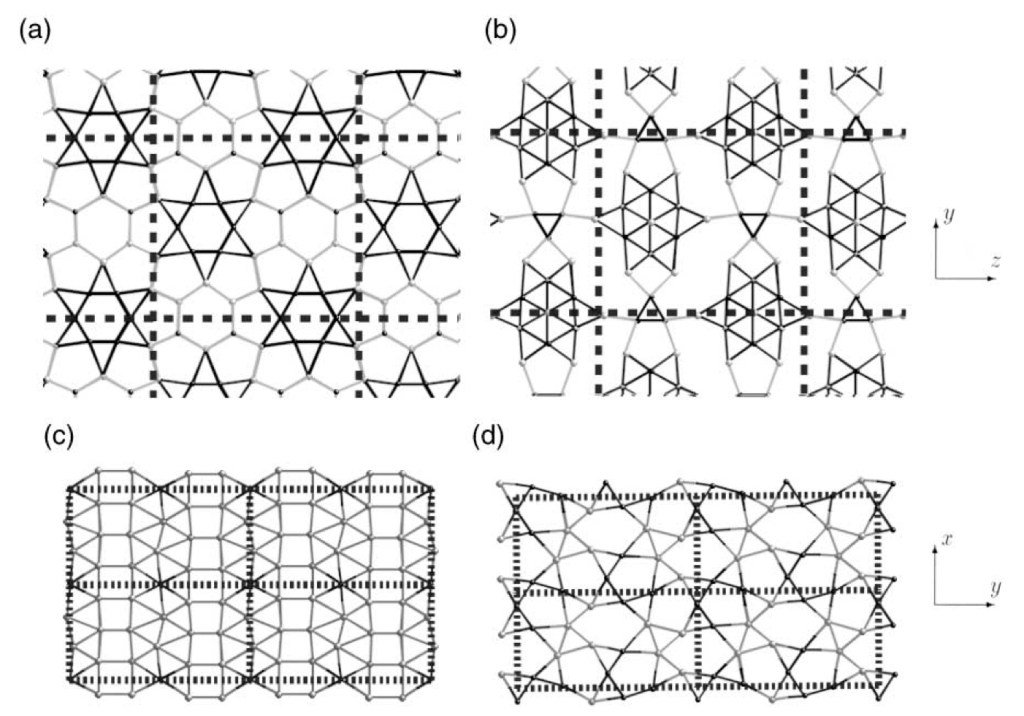

- Al-Cu: in this system the complex structure of the semi-coherent interface of the θ′ (Al2Cu) precipitate phase, in the original Guinier-Preston Al-1.7at.%Cu alloy, was discovered and characterised. This work provides new insights into the atomistics of growth of a precipitate used as a strengthening constituent of many engineering alloys since the Wright Brothers’ famous flight, and as a model system for understanding alloy phase transformations. It was published in 2011 and 2013 in the journals Acta Materialia and Physical Review Letters.

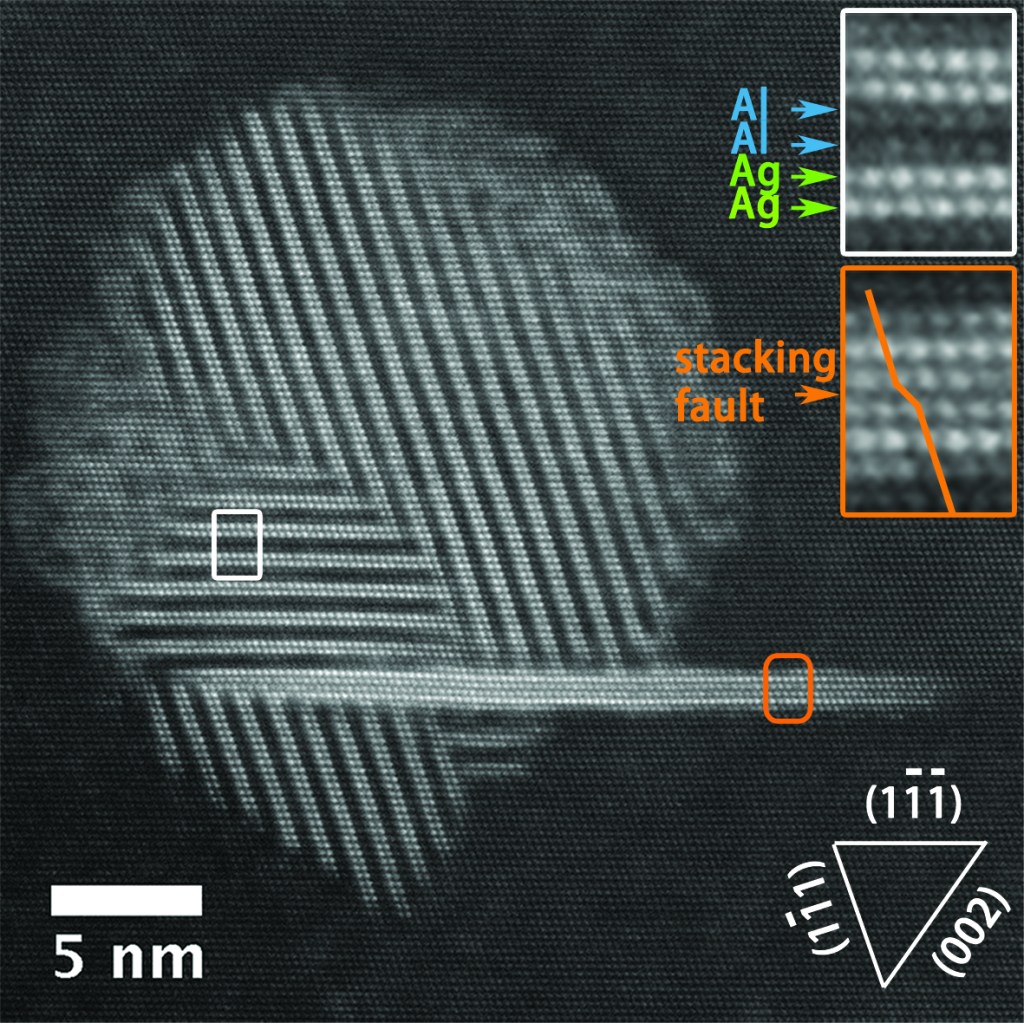

- Al-Ag: other types of complex interfacial structures were characterized and rationalized. This work formed part of Dr Zezhong Zhang’s Ph.D. thesis (2019) and was published in Acta Materialia in 2019.

- Al-Au: The bulk and interfacial structures are very different from those observed in the Al-Cu and Al-Ag alloys, which can be rationalized using first-principles calculations.

Key atomistic mechanisms of nucleation and growth for several classic aluminium alloys.

- Uncovering of the subtle role of vacancies in controlling the precipitation pathways in the classic alloy Al-1.7at.%Cu containing trace additions of In and Sb. This new alloy also exhibits very favourable mechanical properties. This is the Ph.D. work of Dr Yong Zhang.

- Trace additions of gold dramatically increase the strength of Al-Cu alloys. This takes place through a templating nucleation mechanism, as demonstrated through TEM and classical nucleation analysis. This is the work of Research Fellow Dr Yiqiang Chen.

- Clarification of the role of tin as an efficient promoter of θ′ nucleation, which had been in debate for sixty years. The segregation of tin atoms to the matrix-precipitate interface was found to be key. This work confirmed and extended earlier findings that suggested the synergistic interaction between heterogeneous nucleation promoter and the promoted phase.

Determination of crystal structures and new phases in aluminium and magnesium alloys.

- Discovery of a new precipitate phase, z, in the textbook Al-Ag alloy system. This is the first discovery of a new phase in Al-Ag for more than 50 years. This phase forms through the ordering of pre-existing disordered Guinier-Preston zones of the same chemical composition, which can thus be regarded as a chemical template. The zeta structure is related to the Ag interfacial segregation observed on strengthening precipitates. This is the Ph.D. work of Dr Zezhong Zhang.

- The equilibrium phi phase in Mg-Zn-Al. In 2001 we solved the crystal structure including atomic positions of this major intermetallic phase. Our structure solution was found to constitute an excellent starting point for the structure refined using single-crystal X-ray diffraction and first-principles calculations in a modern study (Berthold et al. Intermetallics 32 (2013) 259).

Void formation and evolution in aluminium.

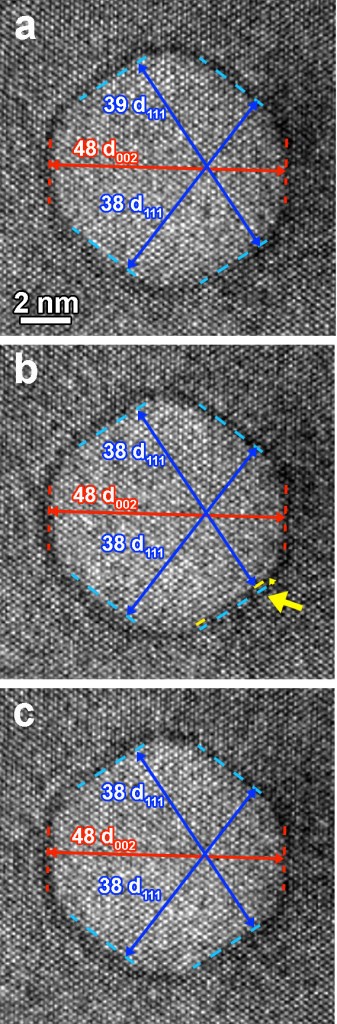

- Voids in materials usually constitute the first sign of mechanical or electrical failure, so understanding their formation and evolution is important. The shrinkage of voids in ultra-pure aluminium was investigated at near atomic resolution and in live time via in situ TEM. The last stages of void shrinkage (when a void is <5 nm in diameter) were found not to conform to the classical theory of diffusion kinetics. This work involved the then undergraduate student Mr Zezhong Zhang, who is first author of the resulting publication.

- Discovery of the formation of voids in association with the solidification of nanoparticles of tin in aluminium. Although this phenomenon is well known in semi-conductors like silicon, this was the first report of voids resulting from a phase transition in a metal.